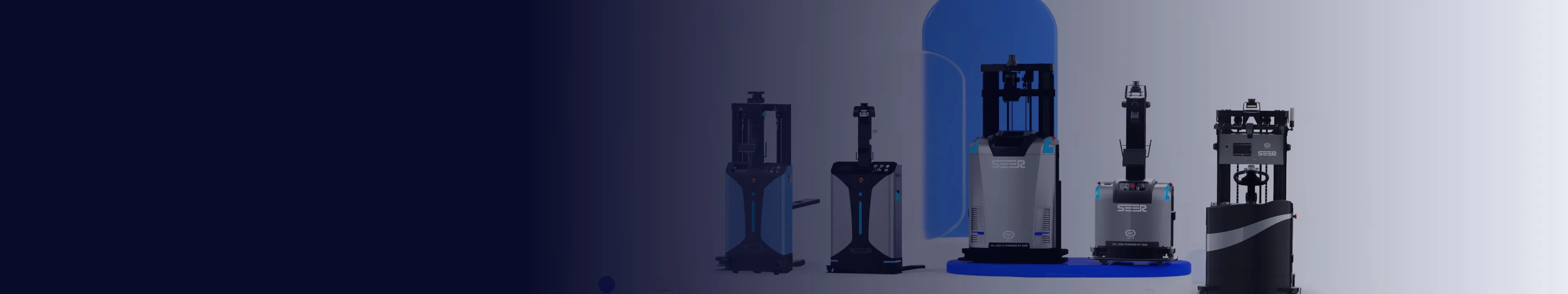

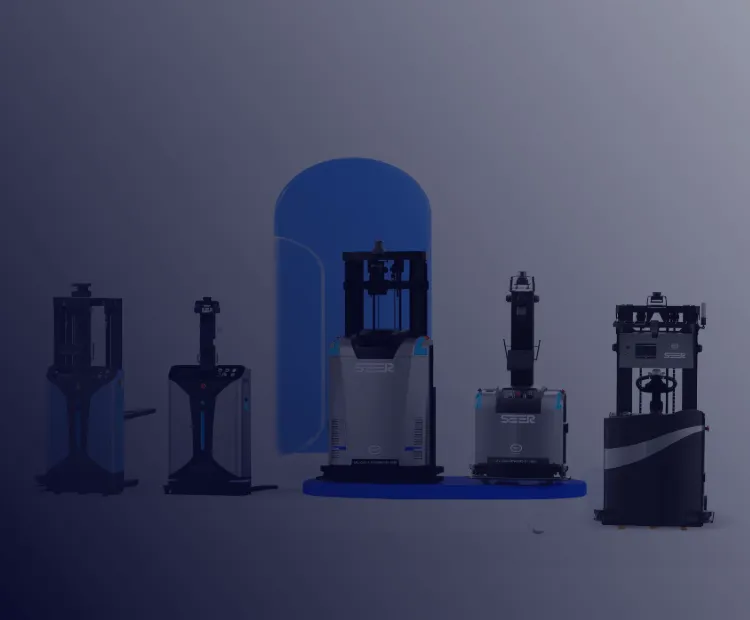

robots, including jacking robots, smart forklifts, picking robots, etc., and is

constantly enriching robot categories to provide customers with more standard

vehicles, more multi-scene mobile robots. All mobile robots have a unified

interface, and with the SEER digital system, they can provide customers with

complete handling and distribution solutions.

Based on the SRC controller, combined with SEER's software RDS (Fleet Management System) and MWMS, effortlessly achieve various solutions with efficiency.

Maximum driving speed of 2m/s in both no-load and full-load cases.

Easy deployment without reflectors and the accuracy can reach up to ±10mm with SLAM navigation.

The modular design guarantees unparalleled reliability and stability and maintenance becomes a breeze, enabling you to save significantly both time and money.

Based on the SRC controller, combined with SEER's software RDS (Fleet Management System) and MWMS, effortlessly achieve various solutions with efficiency.

Maximum driving speed of 2m/s in both no-load and full-load cases.

Easy deployment without reflectors and the accuracy can reach up to ±10mm with SLAM navigation.

The modular design guarantees unparalleled reliability and stability and maintenance becomes a breeze, enabling you to save significantly both time and money.

Based on the SRC controller, combined with SEER's software RDS (Fleet Management System) and MWMS, effortlessly achieve various solutions with efficiency.

Maximum driving speed of 2m/s in both no-load and full-load cases.

Easy deployment without reflectors and the accuracy can reach up to ±10mm with SLAM navigation.

The modular design guarantees unparalleled reliability and stability and maintenance becomes a breeze, enabling you to save significantly both time and money.

Based on the SRC controller, combined with SEER's software RDS (Fleet Management System) and MWMS, effortlessly achieve various solutions with efficiency.

Maximum driving speed of 2m/s in both no-load and full-load cases.

Easy deployment without reflectors and the accuracy can reach up to ±10mm with SLAM navigation.

The modular design guarantees unparalleled reliability and stability and maintenance becomes a breeze, enabling you to save significantly both time and money.

Based on the SRC controller, combined with SEER's software RDS (Fleet Management System) and MWMS, effortlessly achieve various solutions with efficiency.

Maximum driving speed of 2m/s in both no-load and full-load cases.

Easy deployment without reflectors and the accuracy can reach up to ±10mm with SLAM navigation.

The modular design guarantees unparalleled reliability and stability and maintenance becomes a breeze, enabling you to save significantly both time and money.

| Product model | |

|---|---|

| 产品型号 | SFL-CDD14-CE |

| Basic parameters | |

|---|---|

| Product name | Laser SLAM Small Stacker Autonomous Forklift |

| Operation type | Automatic navigation, by manual control device |

| Navigation type | Laser SLAM |

| Pallet type | Open pallet |

| Rated load capacity | 1400 kg |

| Load center distance | 600 mm |

| Weight (with battery) | 680 / 740 kg |

| Standard lifting height | 1600 / 3000 mm |

| Forklift dimensions: L x W x H | P+F: 1722 x 951 x 2064 / 1722 x 951 x 2234 mm |

| Fork dimensions: L x W x H | 1220 x 180 x 70 mm |

| Fork outer width | 555 / 570 / 680 mm |

| Right-angle stacking aisle width, pallet 1000×1200 (1200 placed along the fork) | 1966+200 mm |

| Right-angle stacking aisle width, pallet 800×1200 (1200 placed along the fork) | 1911+200 / 1914+200 / 1936+200 mm |

| Right-angle stacking aisle width, pallet 1000×1000 (1000 placed along the fork) | 1911+200 / 1914+200 / 1936+200 mm |

| Minimum turning radius | 1206+200 mm |

| Ambient temperature and humidity range | TEMP: 0℃ to 50℃ / RH: 10% to 90%, no compression, no condensation |

| Performance parameters | |

|---|---|

| Driving speed: full load / no load | 1.2 / 1.5 m/s |

| Passability (slope / step / gap) | ≤5% / 5 mm / 15 mm |

| Navigation position accuracy | ±10 mm |

| Navigation angle accuracy | ±0.5° |

| Battery parameters | |

|---|---|

| Battery specifications | 24 V / 180 Ah (lithium iron phosphate) |

| Comprehensive battery life | 10 h |

| Charging time (10% to 80%) | 2 h |

| Charging method | Manual / Automatic |

| Function configurations | |

|---|---|

| Lidar number | 1 (SICK nanoScan3 Core / P+F OMD30M-R2000-B23-V1V1D-HD-1L) +3 (2 (SICK nanoScan3 Core) +1 (OLEI LR-1BS2H) ) |

| Wi-Fi roaming | ● |

| 3D obstacle avoidance | ○ |

| Pallet recognition | ○ |

| Cage stack | ○ |

| High shelf pallet recognition | ○ |

| Pallet stack | ○ |

| HMI display | ● |

| Safety configurations | |

|---|---|

| E-stop button | ● |

| Sound and light indicator | ● |

| Braking distance: 1 m/s / 1.5 m/s | ≤30 cm / ≤50 cm |

| 360° laser protection | ● |

| Fork height protection | ● |

| Certifications | |

|---|---|

| ISO 3691-4 | ● |

| EMC | ● |

| UN38.3 | ● |

IN INDUSTRIAL EQUIPMENT MANUFACTURING

plant area of over 5,500 square meters and a footprint of about 15,000 square meters. Owning strong technical force, the customer is committed to providing high-quality high

voltage variable frequency drives, and delivering varied applications as well as comprehensive & complete services.

近日,仙工智能服务的面板制造龙头滁州惠科移动机器人项目正式投入车间使用,助力其打造智能物流车间,最大化提升货物转运效率,为产线全流程业务提供有力支持。

本期客户是世界500强企业,以其创新的科技理念和领先的技术意识为全球客户提供可编程人机界面、工业平板式计算机、图形逻辑控制器和工业信息终端等产品,在国际工控领域具有良好口碑,是业内主导品牌之一。

仙工智能与集萃智造联手,打造西门子工业创新中心展厅,本展厅用于展示西门子智能音响、行车记录仪等多种产品。

本期案例客户的主要从事高压变频器的生产制造研究开发和运用,厂房面积 5500 多平方米,占地面积约 15000 多平方米。客户公司技术力量雄厚,致力于提供高品质的高压变频器,拥有多样化的应用和综合完整的服务。

过去近10年时间,3C行业的巨大繁荣带动了上游制造业的蓬勃发展,而我国3C制造业一直处于劳动密集型的生产制造和加工组装环节,毛利率在10%左右,净利率不足5%,成本管理能力成为各企业的核心竞争力。 随着我国人口红利流失、劳动力成本不断攀升以及制造业用工人数出现断崖式短缺,处于产业链的中下游的3C制造企业发展面临重要抉择。在“智能制造”的风口浪尖上,机器人替代人,实现工厂自动化、智能化升级已经成为3C制造企业发展的重要出路。 作为3C制造业内的头部企业之一,某公司主要从事蓝牙耳机、手机、汽车组件等消费型电子产品及其零组件的加工制造,拥有员工上万人。随着消费者需求不断变化,各品牌商对工厂加工制造提出了更高要求,质量要求提升的同时交付时间缩短,对工厂生产效率要求进一步提升。在人力成本不断攀升和青壮年劳动力招工困难的情况下,该企业下定决心进行自动化、智能化升级。